Towards green architecture trending, insulated glass is increasingly popular and more commonly used in the Vietnamese market with the advantage of reducing power consumption.

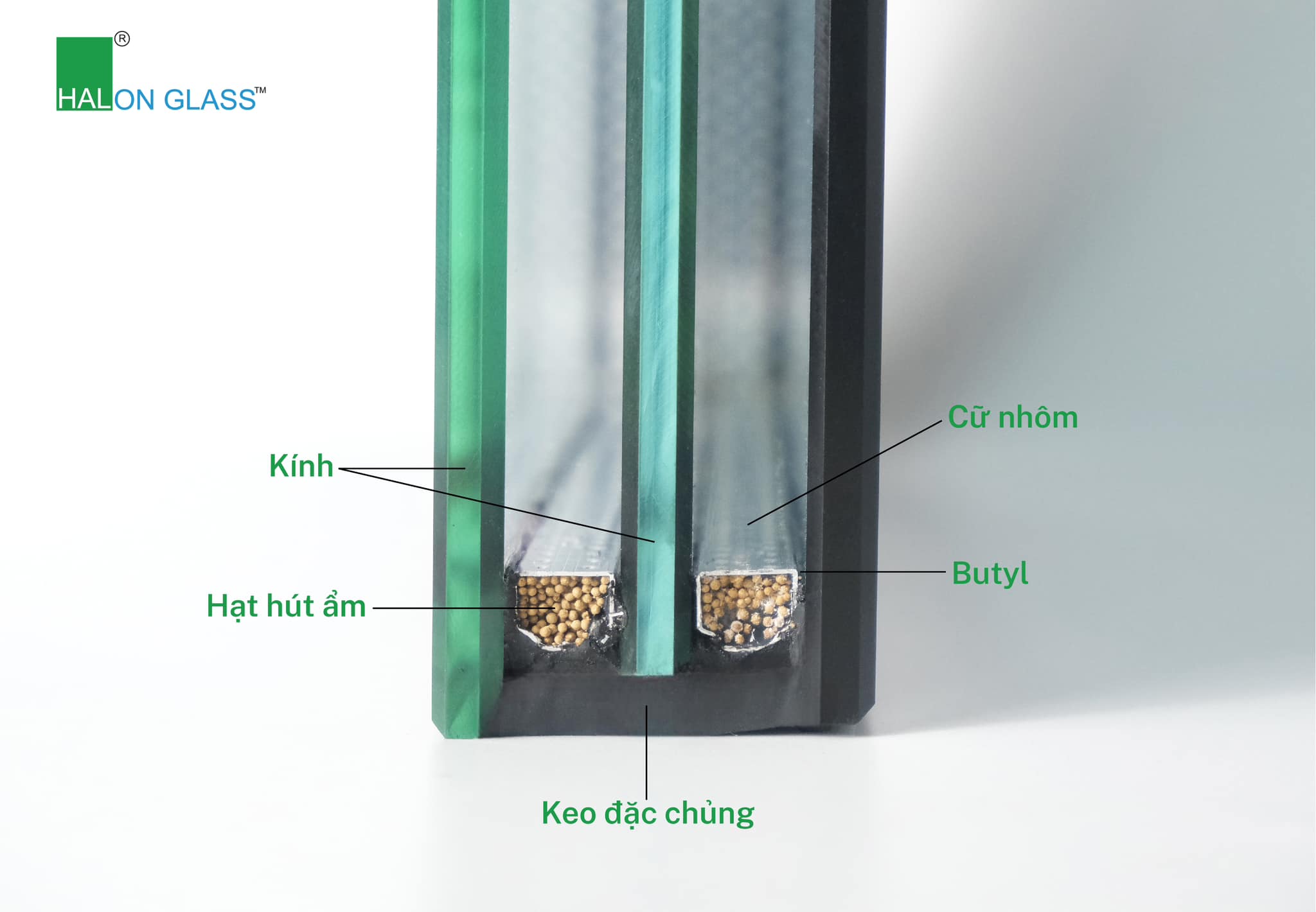

Insulated glass is a special type of glass made from 2 or more layers of glass laminated together, between the layers of glass is separated by a shaped aluminum bar containing desiccant particles and a layer of butyl glue running around the aluminum frame. Creates an absolute tightness between the two environments inside and outside the box. The desiccant particles inside the aluminum frame work to absorb the remaining moist air inside the box, creating a dry air environment, which significantly contributes to the process of preventing heat. In addition, all glass boxes are filled with Argon gas (inert gas) to maximize insulation and avoid condensation.

Structure of insulated glass.

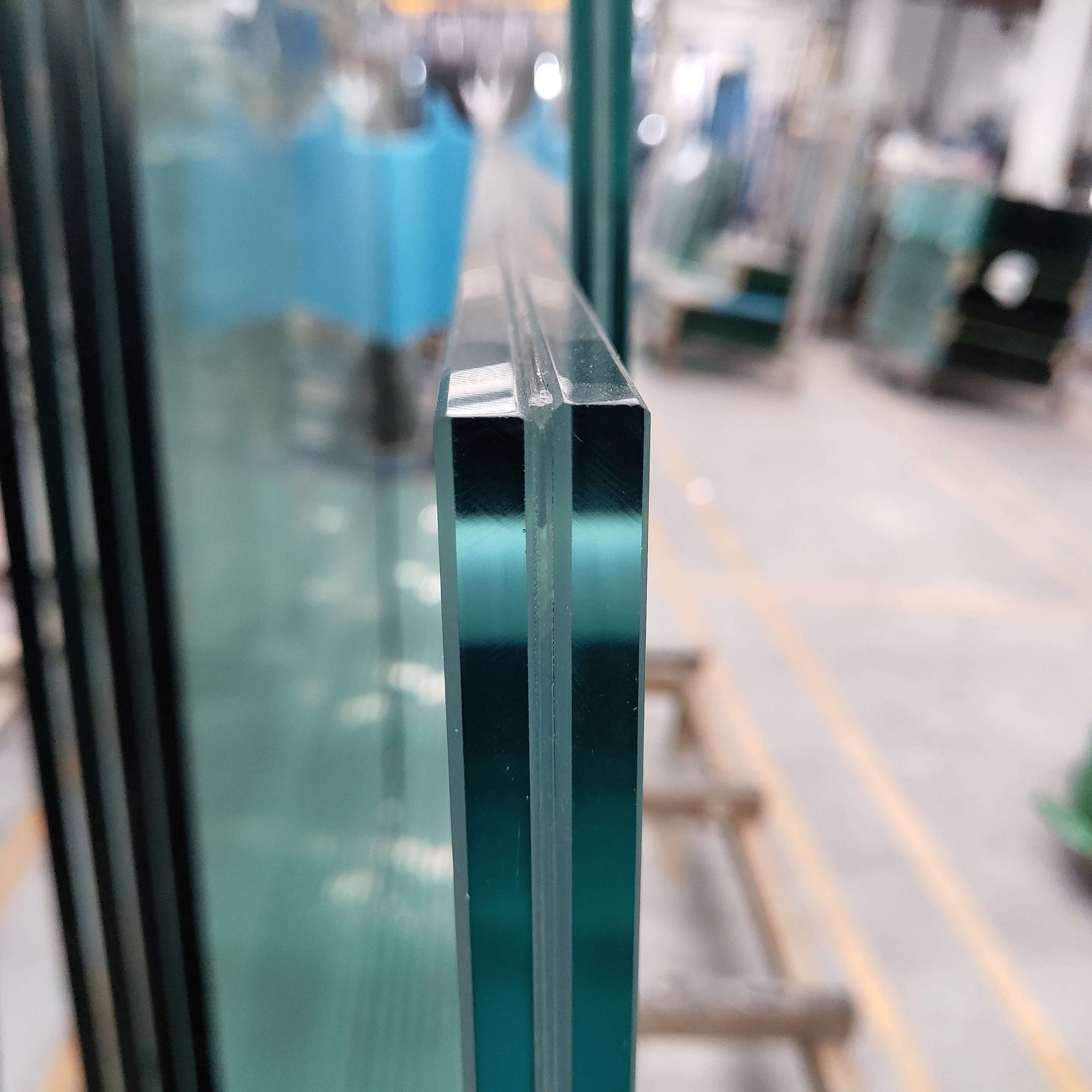

Insulated glass is made up of layers of glass with a thickness of 3 - 10mm, with the flexibility to customize the use of tempered glass, low-e glass, or laminated safety glass for one or more layers of box glass.

The most outstanding advantages when using this type of glass for projects are its heat insulation, sound insulation, and high safety. From there, power consumption from using air conditioning and dehumidifying equipment is also significantly reduced, contributing to environmental protection.

Insulated glass has superior heat and sound insulation properties than annealed glass.

With the above advantages, we believes that insulated glass will become the optimal solution for future projects by not only bringing aesthetic beauty, but also aiming to protect and preserve the green environment.

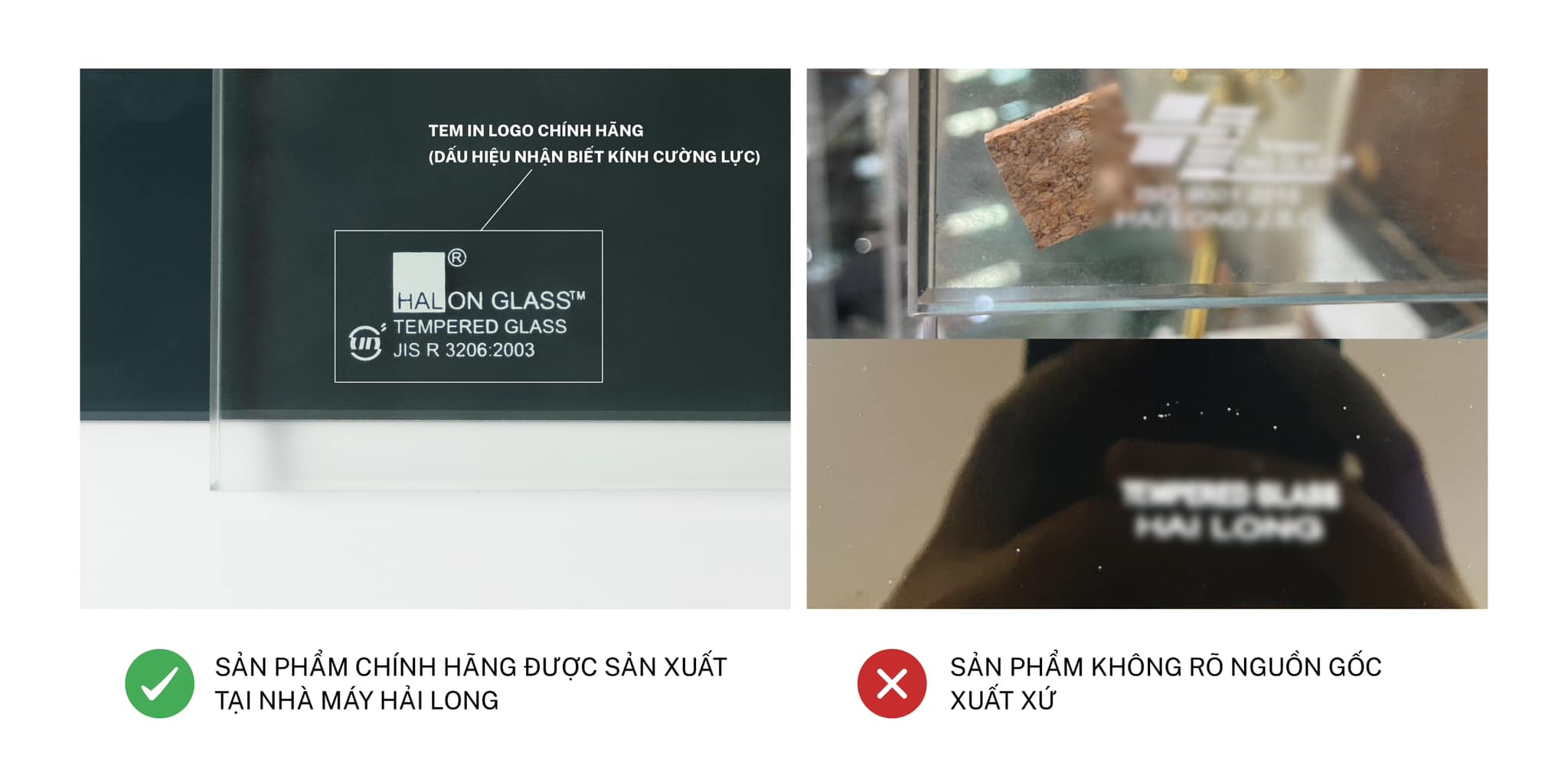

Safety insulated glass products are manufactured at Hai Long factory.

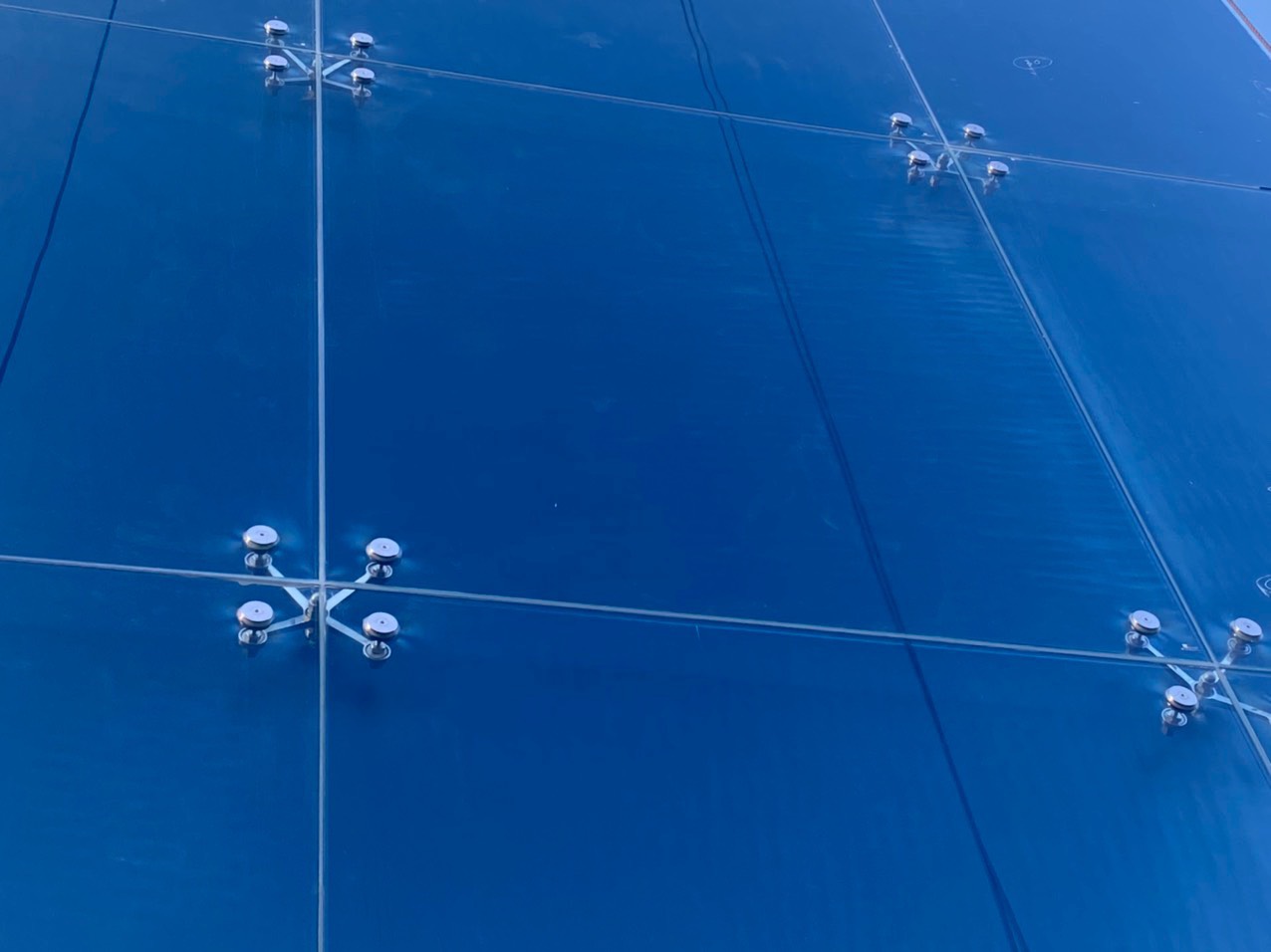

Insulated glass is often used as facades for buildings.

In addition to safety factors, using insulated glass also ensures aesthetics, sound insulation

and heat insulation for the project.